After more than 10 years of research and development, an upgraded tracker that is fundamental to the ATLAS experiment, is moving to production marking a major milestone for the collaboration. ATLAS is a general-purpose particle physics experiment and is one of the four major experiments at the Large Hadron Collider (LHC) at CERN; the experiment is run by an international collaboration and has been designed to exploit the full discovery potential and the huge range of physics opportunities provided by the LHC. The tracking detector measures the trajectories of charged particles and determines their momenta from the curvature in the magnetic field.

Oxford is a founding member of the ATLAS collaboration and is leading on upgrading the experiment readying it for the next phase of LHC: High Luminosity. The High-Luminosity Large Hadron Collider (HL-LHC) project aims to ramp up the performance of the LHC in order to increase the potential for discoveries after 2029. The objective of the HL-LHC is to increase the integrated luminosity by a factor of 10 beyond the LHC’s design value. The ATLAS experiment therefore needs to upgrade its infrastructure to accommodate these changes.

‘The current ATLAS tracker is still working very well nearly 20 years after it was built however, an improved tracker will be needed to cope with the harsher conditions at HL-LHC,’ explains Professor Daniela Bortoletto who leads the ATLAS collaboration at Oxford. ‘The tracker upgrade is now moving into production and final parts are starting to be produced which is incredibly exciting.’

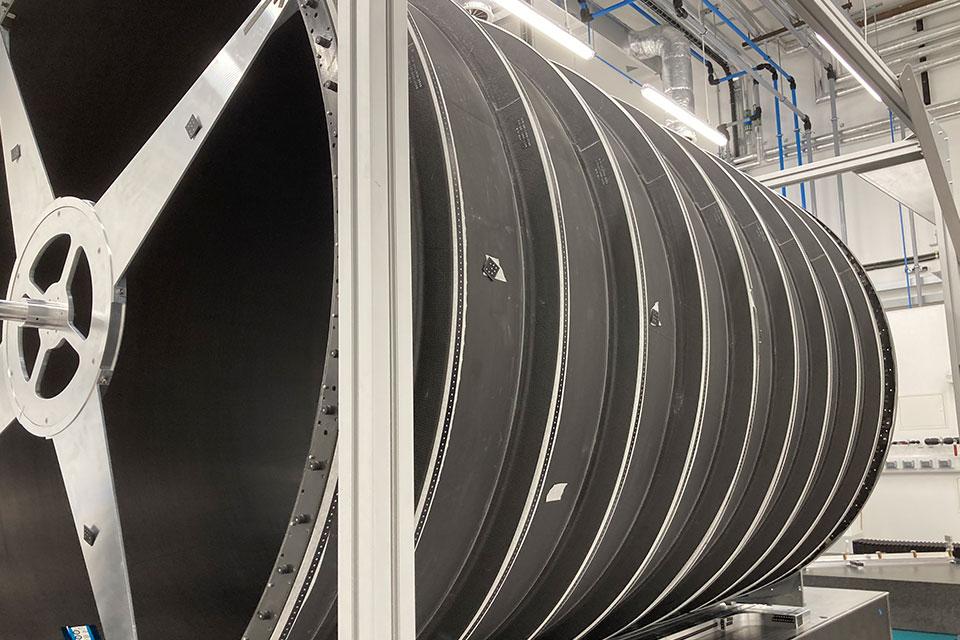

One of the largest parts (see photo above) is the ~2m-diameter carbon fibre cylinder for the outer layer of the strip tracker. The “hoops” visible in the photo help achieve the required stiffness for the minimum amount of material. After a 3D survey, mounting brackets will be attached to the cylinder with a radiation-hard glue. The locations will be precisely determined by tooling specially developed at Oxford. After the cylinder dressing is complete and all the brackets are glued in place, the cylinder will be shipped to CERN by the end of the summer.

The next phase at CERN will be to mount the carbon fibre staves loaded with silicon modules onto this cylinder. The carbon fibre staves provide the mechanical support for the silicon modules and all the electrical, optical and thermal services. There were designed in Oxford and half the number of production staves will be assembled in Oxford. To complete the barrel section of the strip tracker, these steps will be repeated for three smaller cylinders, with the cylinders mounted inside each other like Russian dolls.

Head of the Technical Services Group at Oxford's Department of Physics, Vishal Francis, concludes: 'This work would not have been possible without the specialist facilities in the mechanical workshop and the expertise and the dedication of the engineers and technicians involved in the project.'