Cycle-to-cycle variation analysis of two-colour PLIF temperature measurements calibrated with laser induced grating spectroscopy in a firing GDI engine

SAE International Journal of Advances and Current Practices in Mobility SAE International 1:4 (2019) 1404-1419

Abstract:

In-cylinder temperatures and their cyclic variations strongly influence many aspects of internal combustion engine operation, from chemical reaction rates determining the production of NOx and particulate matter to the tendency for auto-ignition leading to knock in spark ignition engines. Spatially resolved measurements of temperature can provide insights into such processes and enable validation of Computational Fluid Dynamics simulations used to model engine performance and guide engine design. This work uses a combination of Two-Colour Planar Laser Induced Fluorescence (TC-PLIF) and Laser Induced Grating Spectroscopy (LIGS) to measure the in-cylinder temperature distributions of a firing optically accessible spark ignition engine. TC-PLIF performs 2-D temperature measurements using fluorescence emission in two different wavelength bands but requires calibration under conditions of known temperature, pressure and composition. Here the TC-PLIF technique is calibrated in-situ using high precision (<1%) LIGS point measurements. Temperature distributions were recorded during the compression stroke for fired operation with Direct Injection and with Plenum Fuel Injection of three two-component fuels containing toluene and iso-octane. Temperature inhomogeneity was observed for all fuels and injection strategies, with mm-scale regions having temperatures up to 10% higher than the local environment. Charge cooling of 3% due to direct injection was resolved. Proper Orthogonal Decomposition (POD) was used to quantify the cycle-to-cycle variation of the temperature data. Low-order POD modes featured most of the cyclic variation in temperature and the corresponding mode coefficients were used to investigate correlations with combustion analysis, fuel injection strategies and toluene content of the fuel. Additionally, the low-order POD mode coefficients provided an opportunity to identify cycles containing local hotspots or outlier measurements.Temperature measurements under diesel engine conditions using laser induced grating spectroscopy

Combustion and Flame Elsevier (2018)

Abstract:

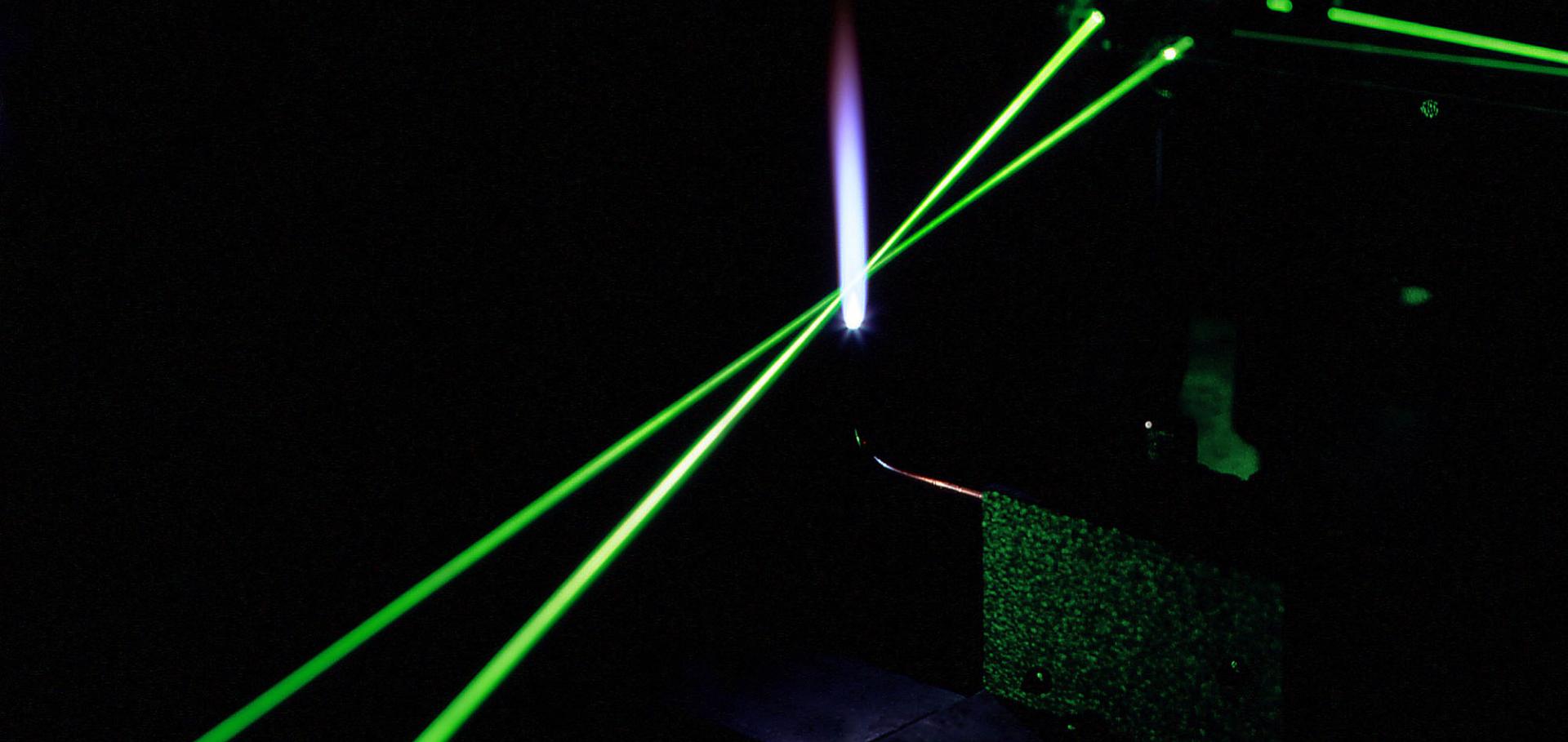

Crank angle-resolved temperatures have been measured using laser induced grating spectroscopy (LIGS) in a reciprocating rapid compression machine (RCM) to simulate diesel engine operating conditions. A portable LIGS system based on a pulsed Nd:YAG laser, fundamental emission at 1064 nm and the fourth harmonic at 266 nm, was used with a c.w. diode-pumped solid state laser as probe at 660 nm. Laser induced thermal grating scattering (LITGS) using resonant absorption by 1-methylnaphthalene, as a substitute fuel, of the 266 nm pump-radiation was used for temperature measurements during non-combusting cycles. Laser induced electrostrictive grating scattering (LIEGS) using 1064 nm pump-radiation was used to measure temperatures in both combusting and non-combusting cycles with good agreement with the results of LITGS measurements which had a single-shot precision of ± 15 K and standard error of ± 1.5 K. The accuracy was estimated to be ± 3 K based on the uncertainty involved in the modified equation of state used in the derivation from the LIGS measurements of sound speed in the gas. Differences in the in-cylinder bulk gas temperature between combusting and non-combusting cycles were unambiguously resolved and temperatures of 2300 ± 100 K, typical of flames, were recorded in individual cycles. The results confirm the potential for LIGS-based thermometry for high-precision thermometry of combustion under compression-ignition conditions.High frequency measurement of temperature and composition spots with LITGS

Journal of Engineering for Gas Turbines and Power American Society of Mechanical Engineers 141:3 (2018) 031003

Abstract:

Temperature and composition spots in a turbulent flow are detected and time-resolved using laser-induced thermal grating spectroscopy (LITGS). A 355 nm wavelength particle image velocimetry laser is operated at 0.5–1 kHz to generate the thermal grating using biacetyl as an absorber in trace amounts. In an open laminar jet, a feasibility study shows that small (≃ 3%) fluctuations in the mean flow properties are well captured with LITGS. However, corrections of the mean flow properties by the presence of the trace biacetyl are necessary to properly capture the fluctuations. The actual density and temperature variation in the flow are determined using a calibration procedure validated using a laminar jet flow. Finally, traveling entropy and composition spots are directly measured at different locations along a quartz tube, obtaining good agreement with expected values. This study demonstrates that LITGS can be used as a technique to obtain instantaneous, unsteady temperature and density variations in a combustion chamber, requiring only limited optical access.Flame thermometry using laser induced grating spectroscopy of nitric oxide

Applied Physics B Springer 124 (2018) 43

Abstract:

A systematic study of laser-Induced thermal grating scattering (LITGS) using nitric oxide as an absorbing species is presented as a means of thermometry in air-fed combustion. The relative contributions to the scattered signal from degenerate four-wave mixing, DFWM, and from laser induced thermal grating scattering, LITGS, are studied in the time domain for NO in N2 buffer gas up to 4 bar, using a pulsed laser system to excite the (0,0) -bands of NO at 226.21 nm. LITGS signals from combustion-generated NO in a laminar, pre-mixed CH4/O2/N2 flame on an in-house constructed slot burner were used to derive temperature values as a function of O2 concentration and position in the flame at 1 bar and 2.5 bar total pressure. Temperature values consistent with the calculated adiabatic flame temperature were derived from averaged LITGS signals over 50 – 100 single shots at 10 Hz repetition rate in the range 1600 K – 2400 K with a pressure-dependent uncertainty of ±1.8% at 1 bar to ±1.4% at 2.5 bar. Based on observed signal-to-noise ratios the minimum detectable concentration of NO in the flame is estimated to be 80 ppm for a 5 second measurement time at 10 Hz repetition rate.Mixing characterization of highly underexpanded fluid jets with real gas expansion

Experiments in Fluids Springer Verlag 59 (2018) 44